$0.00

Cylinder Repair Process

SP Cylinders cylinder repair process involves customers removing all additional parts before sending them to prevent extra charges or potential damage during removal. Upon receipt, cylinders are tracked, cleaned, undergo old coating removal, sorting for necessary operations, preplating processes, electroplating, honing, and final inspection before dispatch, ensuring adherence to specified standards and protection during delivery.

.

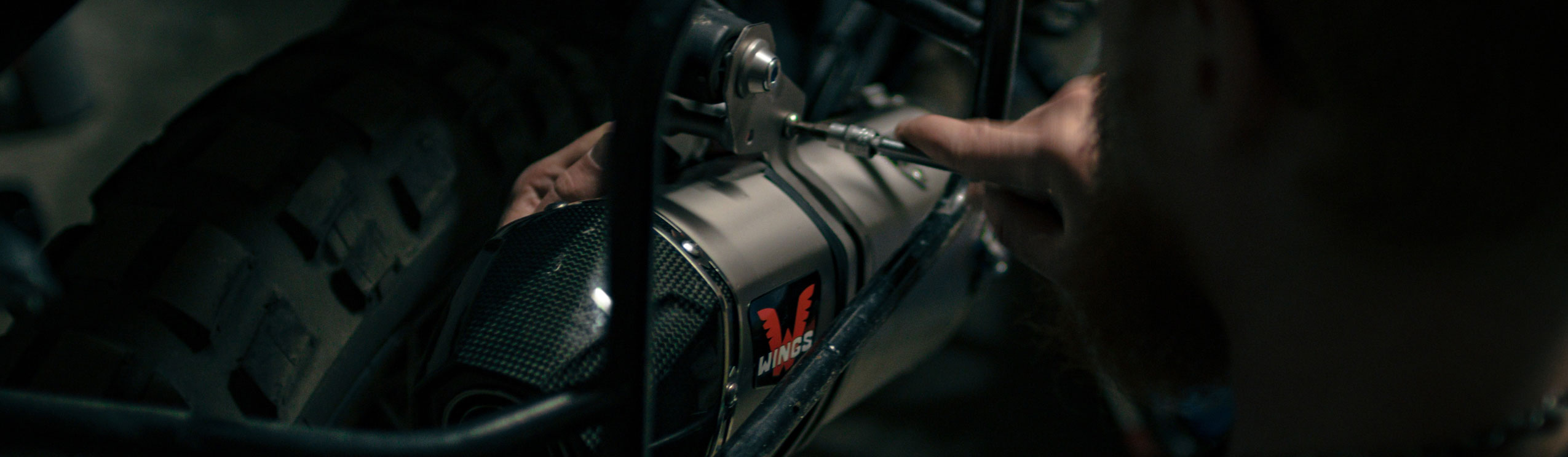

Replating a cylinder using our process

Stage 1: Cylinder Prep & Shipping

A lot of our customers want to know what the steps are in our repair process.

Once you decide to send your cylinder to SP Cylinders LLC, please remove all parts (studs, power valves, lugs, bushes etc.) to avoid additional charges to remove or protect these parts. PLEASE NOTE that if we have to remove parts ourselves, those parts may be damaged or destroyed and may not be returned to you. Please note that our staff are not authorised to vary that Condition of Sale verbally. Make sure that you package your cylinder/s securely to prevent any damage in transit. If you are including a piston, don’t put it into the bore and make sure it is well protected. We recommend sending items to us via a tracked delivery service.

Cylinder tracking

Once we receive your cylinder we will etch a reference number onto it and log it into our computer system. That makes it possible for us to keep track of where a cylinder is and what we need to do with it next. We also write the same number on any pistons or studs etc. so that we can keep track of them too.

Extra parts

If cylinders come in with any studs, power-valves, dowels etc, they

must be removed (or masked) before the cylinder can be stripped. Any

parts that are removed are identified with the cylinder number and

forwarded to the Shipping Department so that we can include them with

the cylinder when it is despatched.

Stage 2: Inspection, Cleaning, Vapor Blasting and Plating

Cleaning & Inspection

After we have done this and given it a first initial inspection, it will then go on to be thoroughly cleaned so that we can REALLY inspect it for any further damage that wasn’t picked up on first initial inspection. We use a variety of cleaners and vapour blasting techniques to clean the cylinders.

Old coating removal

Once the cylinders are cleaned and all the non-aluminium parts have been removed or protected, we must remove the old coating within the bore. This is normally done by immersion in an acid solution specially selected to avoid damaging the aluminium itself.

Preplating

Before we plate a cylinder, we want it to be a specific diameter. The boring operations are not accurate enough for this task, so we treat those as “roughing” processes and we hone the cylinders to our required preplate size. After the honing operation, the cylinders will be very oily. Oil is never allowed near the plating chemicals, and so the cylinders must be thoroughly cleaned before plating. We use a combination of solvents and detergents to clean all traces of oil from the part.

Cylinder electroplating

Now that the bores have been made straight, round and the right size, we can apply our new electroplated coating. The cylinders are treated in a variety of chemicals to condition the surface before having anodes installed and connected; the plating process is then started. The plating time and current are calculated by computer and, after the time has passed, the cylinders are rinsed, dried and bead blasted to really clean them up and make them look like new again.

Cylinder Sorting

After the cylinders are stripped, they must be sorted to go to the correct next operation.

The three common choices are:

- Send for welding

- Send for boring

- Send for honing

If a cylinder is cracked, scored or damaged in any other way, we can usually repair it by welding and re-machining. The welding process adds aluminium to the damage and builds up any scores. After welding, cylinders must be bored, honed to preplate size and the ports must be reshaped and chamfered before plating.

Please be aware that in some cases when you send your cylinder to us you may think that it only needs replating, then when we have removed the coating we can find underlying problems like cracks etc. This will have to then be repaired before a new coating can be applied.

Stage 3: Final Honing, Final Inspection & Return Shipping

Honing

Once plated and cleaned on the outside, cylinders face a multi-stage honing process. “Pre-honing” comes first and the main purpose of this operation is removing the extra plating build-up that occurs at port edges etc as a normal part of the electroplating operation. This helps to protect the shape of our very expensive diamond honing tools so that they keep producing accurate bores for as long as possible without unnecessary maintenance.

In our next honing process, we use three progressively finer grades of diamond abrasives. Our “roughing diamonds” remove material quickly but leave a surface finish that is too coarse to be used in an engine cylinder. This stage still produces straight, round bores but we stop cutting a little before we reach our intended finished size. After the bore is “rough honed”, the cylinder goes to a chamfering station where all port-edges are ground by hand, and then the “head-face” is checked for flatness on a surface plate. This work may leave small burrs that could damage an engine if they aren’t removed. The small burrs that might be around the ports after the chamfering operations are removed during finish honing. This step also produces the correct surface finish and the precise bore sizing.

Inspection & Return Shipping

Finally we clean the cylinder once again; we must then inspect it visually to confirm that everything we have done is to the correct standard. If everything is ok, it goes to the Shipping Department where we carry out a final check that the correct work has been done, that it’s to the correct standard, that any pistons, studs etc are being returned with the cylinder, and that the completed package is well protected against damage during delivery.

Advanced Nikasil Cylinder Plating and Repair Services.

Unlock the full potential of your engine with our cutting-edge Nikasil repair services and cylinder repair solutions. Our unrivaled expertise in the industry, SP Cylinders is your go-to partner for maximizing the life and power of your cylinders.

Need Help?

Store Information

- Vapor Honing Service - 5 Day Turn Around Time

- Cylinder Repair Service - 10 Day Turn Around Time